Stainless Steel Bearing Housing for Hammer Mills - Pulva

This is a subtitle for your new post

A customer recently approached Pulva Corporation about cleaning and sanitizing issues they were having on their cosmetic manufacturing hammer mill. They were experiencing significant down time while carrying out cleaning tasks. Several areas were discussed and it was decided that the bearing housings would be addressed first. The cleaning agent contained ingredients that removed paint and rusted traditional bearing housing materials like cast iron. The cast housings also had an irregular surface that made wipe downs time consuming.

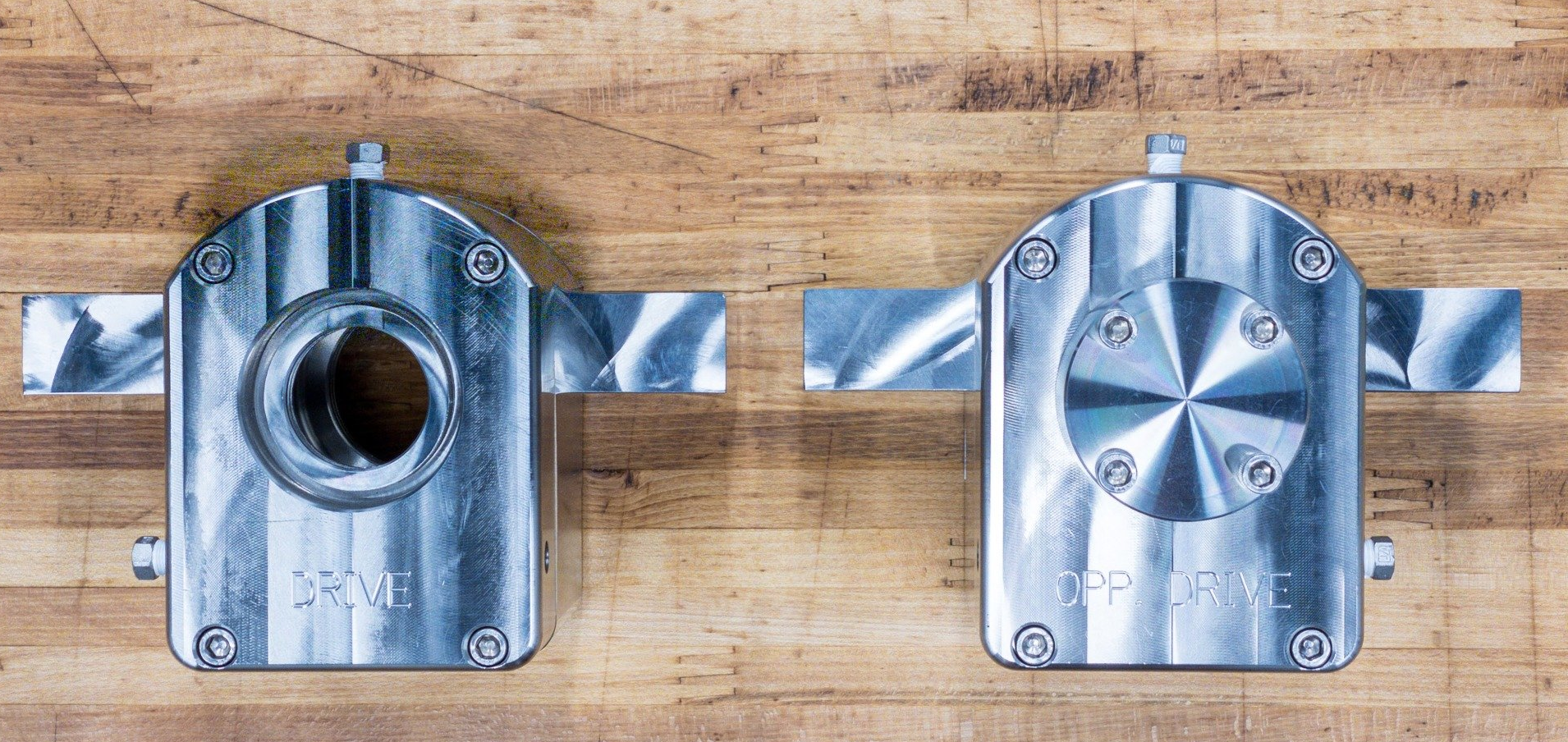

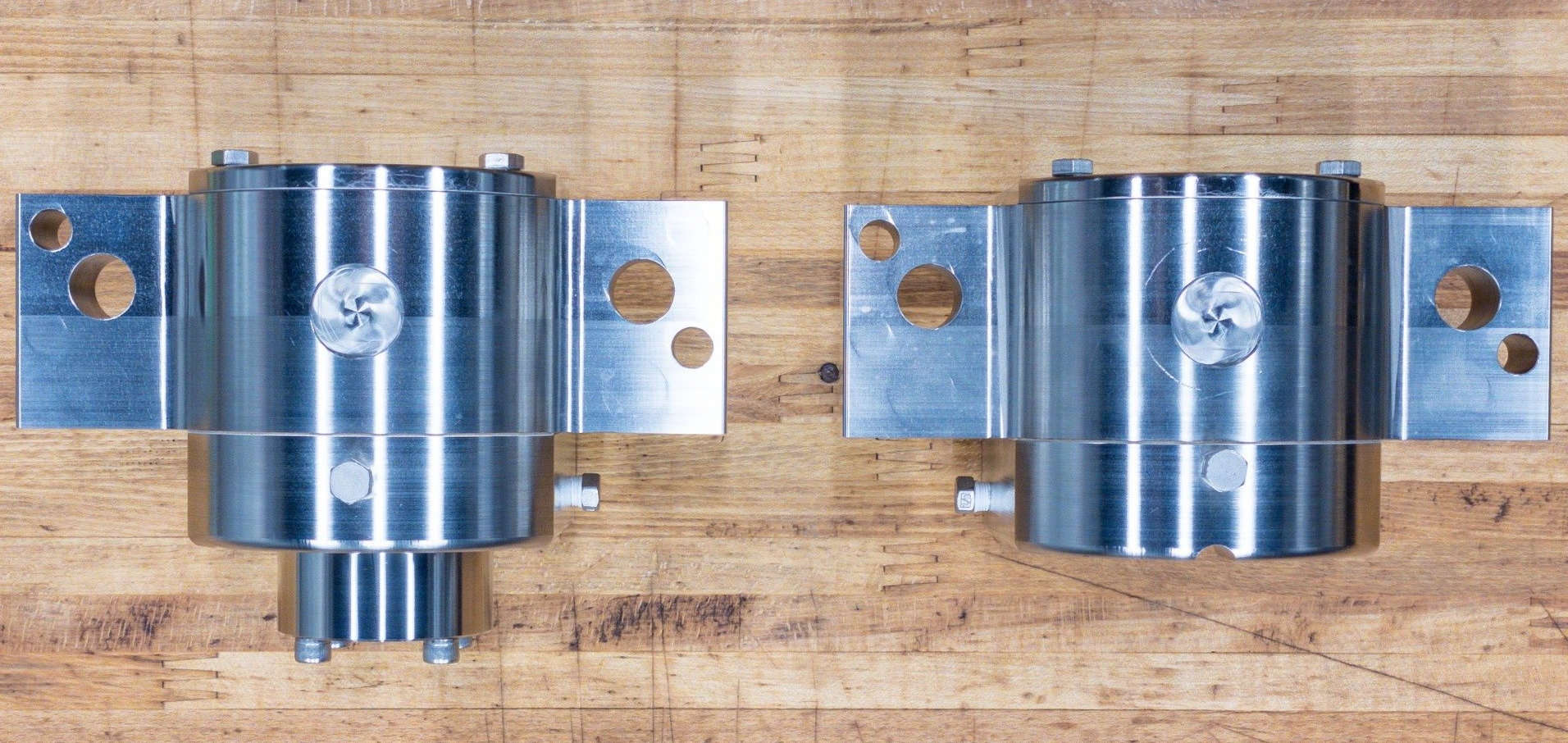

A 316 stainless bearing housing was requested and Pulva delivered a modular designed billet (made from solid material rather than a traditional casting) 316 stainless bearing housing. The housings were designed with smooth and accessible surfaces. Surface cleaning time was reduced and cosmetic manufacturing time increased because of the smoothness of the housings. The housings can be applied in food and pharmaceutical industries as well.

Pulva is currently planning the next project and asks for customer input. What are your hammer mill cleaning issues? In what areas do you experience downtime due to inaccessible or hard to clean surfaces?

Rotor assemblies

Gearbox and drive assemblies

Main body housing

Main cover housing with deflector liner

Mill support frame

Others

email: sales@pulva.com

Please feel free to provide your input on the next cleaning and sanitizing project. Currently Pulva is focusing on the Model B hammer mill and #2 micro pulverizer. Other models will be addressed as requested.